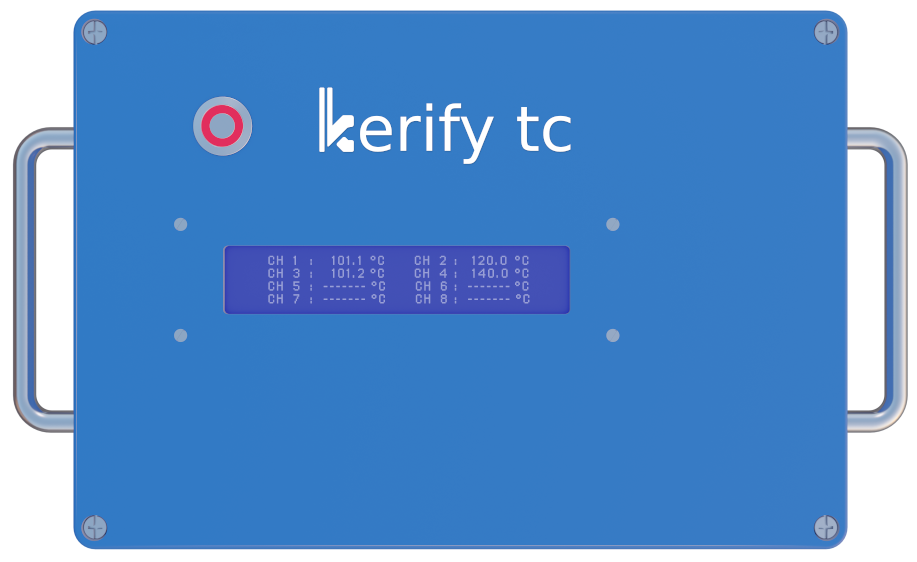

kerify tc

Modular measurement & control system, kerify tc – Made in Switzerland.

kerify can be used as a data logger (measurement acquisition system) for various measurements as well.

💡 ONLINE-DEMO

Would you like to see the system in action? Contact us for an online demonstration.