Simulation

Simulation-Based Optimization of Inductive Heating Processes and Components

From rough power estimation of an inductive heating process to the optimization of complex inductor geometries – simulation can handle it all.

Simulation

From rough power estimation of an inductive heating process to the optimization of complex inductor geometries – simulation can handle it all.

In most areas where there are multi-physical phenomena (in the case of induction heating electro-magnetic, thermal, and sometimes even fluid dynamics), numerical simulation has become indispensable. Simulation software is an important tool, especially if a coil or the workpiece geometry is complex. Simulations can save time, costs, energy, and resources.

For example, in coil manufacturing, there are oftentimes multiple restrictions in terms of temperature distribution in the workpiece, geometry of the induction coil and desired resonant frequency to match with the circuit of the induction generator. This leads to many coil candidates, and it would be very time consuming and costly to build and test them all. The accuracy of simulations even allow virtual coil design.

Thanks to additive manufacturing (for example SLM – selective laser melting) there are less restrictions, and the theoretically best coil geometry can be built – again and again, with the same quality (and high reproducibility).

Furthermore, the visualization of fields such as current distribution, magnetic field and of course the temperature distribution in the workpiece strengthens the understanding of the underlying physics and leads to higher product quality.

If you are interested to learn more about induction heating, just get in touch with us.

Price list

Feasibility and Performance Estimation

◒ Feasibility

◒ Performance Estimation

from CHF 250

Precise Calculation Including Material Research

◒ Feasibility

◒ Performance Estimation

◒ Material Research

Price available upon request

Model Validation with Real Heating Experiments

◒ Feasibility

◒ Performance Estimation

◒ Material Research

◒ Model Validation

Price available upon request

💡 Customised Feasibility Study according to customer specifications are also available. Please contact us at heat@kottonau.ch

In the case of recurring simulations, we offer simulation subscriptions at attractive prices (more details will follow soon).

Example: Troubleshooting

An experienced specialist in the field of inductive heating can usually identify the origin or cause of unsatisfactory heating patterns, or why an induction coil fails over time, without resorting to simulation. However, multiphysical finite element calculations can provide quantitative insights to solve a heating issue.

Example: Power estimation

Rough estimation of needed generator power based on heating time, workpiece material, desired temperature distribution etc.

Example: Maximize induction coil lifetime

Optimisation of induction coil cooling, to increase lifetime.

Example: Optimize induction coil geometry

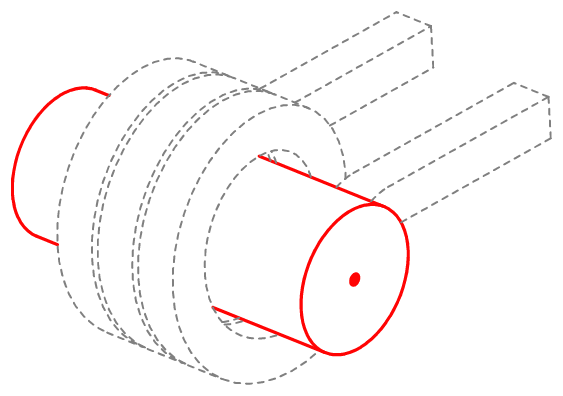

Determine optimal induction coil geometry under consideration of desired temperature distribution, workpiece material, frequency and other application specific restrictions.

Example: Determine PID control parameters with Simulation

Many temperature controllers have a built-in autotune feature. Unfortunately, this automatic determination of control parameters doesn’t always work reliably and is time- and material-intensive to find good values. By simulating the heating process (i.e., virtual heating experiments), these parameters can be determined and optimized. Furthermore, for example, the optimal hold time can be determined, thereby saving valuable energy and, of course, minimizing cycle time.

Possibilities

Tools: We work with contemporary software, including COMSOL and Solidworks.

Remo Kottonau

Application Engineer

Tel : +41 (0) 55 264 11 47

E-Mail :

remo@kottonau.ch